Procedure

1. Please refer to the "Internal Controls Procedures" for manual procedures that

are critical to ensuring an effective control environment for this activity.

2. Start the activity using the appropriate menu path or transaction code as

applicable.

3. Perform one of the following:

|

If

|

Then

|

Go To

|

|

Creating Outbound Delivery Document

|

Use transaction

code VL01N

|

Step 4

|

|

Changing Outbound Delivery Document

|

Use transaction

code VL02N

|

Step 12

|

|

Displaying Outbound Delivery Document

|

Use transaction

code VL03N

|

Step 34

|

|

Posting Goods Issue manually for GL2 Personal Care and GL3

Sell from Stock

|

Use transaction

code VL06G

|

Step 41

|

|

Printing and/or e-mailing Delivery Document to vendor and

Shipment Confirmation to customer for GL2 Personal Care and GL3 Sell from

Stock

|

Use transaction

code VL03N

|

Step 51

|

|

Reversing Post Goods Issue

|

Use transaction

code VL09

|

Step 64

|

|

Exiting this procedure

|

|

Step 75

|

4. Use transaction code VL01N to Create Outbound Delivery with Order Reference

Create

Outbound Delivery with Order Reference

5. As required, complete/review the following fields:

|

Field Name

|

R/O/C

|

Description

|

|

Shipping point

|

R

|

Physical location from

which an item is shipped.

This will be the site from

which the outbound shipment will be shipped. This will be the site from

which the outbound shipment will be shipped.

Example: Z015

|

|

Selection date

|

R

|

Delivery of goods will

be selected for processing based upon this date.

If a Sales Order is also

entered, the system checks the delivery selection date against each schedule line for each item. If either the material availability date

or the transportation planning date

falls on or before the delivery selection date, the system copies the item

into the delivery. If a Sales Order is also

entered, the system checks the delivery selection date against each schedule line for each item. If either the material availability date

or the transportation planning date

falls on or before the delivery selection date, the system copies the item

into the delivery.

The current date is the

default value.

|

|

Order

|

R

|

Sales, production,

process, purchase, internal, or work order number that uniquely identifies a

document.

Sales Order number. Sales Order number.

Example: 50000477

|

6. Click  to go to the "Delivery XXXX Create: Overview" screen.

to go to the "Delivery XXXX Create: Overview" screen.

Delivery

XXXX Create: Overview

Many of the required fields are

populated from the Sales Order data.

Many of the required fields are

populated from the Sales Order data.

The Item Overview tab

The Item Overview tab  is the default view. The other tab areas

are typically used to update the data of an existing Delivery Document.

is the default view. The other tab areas

are typically used to update the data of an existing Delivery Document.

7. As required, complete/review the following fields:

|

Field Name

|

R/O/C

|

Description

|

|

Ship-to party

|

R

|

Person or company that

receives the goods.

LBI customer the goods are

being shipped to. LBI customer the goods are

being shipped to.

Example:

20000012

|

|

Planned GI

|

R

|

Description of this term

Planned Goods Issue date of the

outbound shipment. Planned Goods Issue date of the

outbound shipment.

Example: 12/13/2005

|

|

Actual GI

|

O

|

Actual Goods Issue date.

For a Return Shipment, Actual GI is the date the return shipment is received

from the customer. The Goods Receipt execution will have an impact on inventory

and finance.

Actual Goods Issue date of the

outbound shipment to the customer, if different from the planned date.

Posting the Goods Issue creates the Article Document and the Accounting

Document that generate the financial inventory postings. Actual Goods Issue date of the

outbound shipment to the customer, if different from the planned date.

Posting the Goods Issue creates the Article Document and the Accounting

Document that generate the financial inventory postings.

|

|

Total Weight

|

R

|

The total gross weight

of all articles being ordered

Weight of the shipment. Weight of the shipment.

Example: 40 oz

|

|

Article

|

R

|

The smallest unit that

can be sold to a customer or replenished individually using replenishment

planning. An article is also the lowest level at which inventory can be

managed.

Example: 20000255

|

|

Delivery quantity

|

R

|

Quantity of material to

be delivered.

Example: 10

|

|

SU

|

R

|

Sales Unit of Measure.

Example: EA

|

|

Description

|

R

|

Text to identify and

characterize an object or activity.

Description of the articles

that are being sent to the customer. Description of the articles

that are being sent to the customer.

Example: 4 OZ MASS OI,

Eucalyptus Spearmint, Shelf

|

|

Supply Site

|

R

|

The site from which the

shipment is being sent.

Example: Z015

|

Use

Use

to scroll the item lines to the left and right to

view hidden fields.

to scroll the item lines to the left and right to

view hidden fields.

8. Click  to save the

Delivery Document.

to save the

Delivery Document.

The system displays the message,

"Delivery XXXX has been saved". The Delivery Document number is generated

by the system and listed in the system message and in the Outbound Deliv. field.

The system displays the message,

"Delivery XXXX has been saved". The Delivery Document number is generated

by the system and listed in the system message and in the Outbound Deliv. field.

9. Click  to exit the

transaction.

to exit the

transaction.

10. Go to step 3 to select another Delivery

transaction or to exit the activity.

11. The Create Outbound Delivery activity is completed.

12. Use transaction code VL02N to Change Outbound Delivery:

Change Outbound Delivery

13. As required, complete the following field:

|

Field Name

|

R/O/C

|

Description

|

|

Outbound Delivery

|

R

|

Document generated in

SAP that triggers pick, pack and ship activities.

Outbound Delivery Document number. Outbound Delivery Document number.

Example: 80000311

|

14. Click  to go to the Delivery XXXX Change: Overview screen.

to go to the Delivery XXXX Change: Overview screen.

Delivery

XXXX Change: Overview

For personal care, if the Sales Order ships

from a Limited Brands Distribution Center, the Pick

Quantity, Total Weight, No. of packages (cartons), Batch numbers (if applicable), and relevant

comment Text will be updated by the

interface with the Shipping/Picking system (PKMS) used at the Limited Brands

Distribution Centers. Alternately, if the Sales Order ships from a vendor

location, these data items will be provided by the vendor associated using the

Collaboration Hub (CHub) application interface.

For personal care, if the Sales Order ships

from a Limited Brands Distribution Center, the Pick

Quantity, Total Weight, No. of packages (cartons), Batch numbers (if applicable), and relevant

comment Text will be updated by the

interface with the Shipping/Picking system (PKMS) used at the Limited Brands

Distribution Centers. Alternately, if the Sales Order ships from a vendor

location, these data items will be provided by the vendor associated using the

Collaboration Hub (CHub) application interface.

For apparel, the Delivery Document is

updated when the Post Goods Issue is executed on the Outbound Delivery, from

the 3 Way Matching Report between the Factory, Forwarder/Consolidator and CFS

EDI feeds of carton count. The Pick Quantity is updated from the

Inbound Delivery that is created from the Factory 856 ASN EDI feed. The

shipment details such as MAWB/OBOL number, Broker

reference, DO date, Trailer number and Vessel

name are updated from the Consolidator, Forwarder,

Customs and CFS EDI feeds.

For apparel, the Delivery Document is

updated when the Post Goods Issue is executed on the Outbound Delivery, from

the 3 Way Matching Report between the Factory, Forwarder/Consolidator and CFS

EDI feeds of carton count. The Pick Quantity is updated from the

Inbound Delivery that is created from the Factory 856 ASN EDI feed. The

shipment details such as MAWB/OBOL number, Broker

reference, DO date, Trailer number and Vessel

name are updated from the Consolidator, Forwarder,

Customs and CFS EDI feeds.

For apparel sell from

stock such as the Vendor Managed Inventory (VMI) scenario, the Delivery

document needs to be updated manually with the Pick Quantities as it does not

go through the 3 Way Matching Report

For apparel sell from

stock such as the Vendor Managed Inventory (VMI) scenario, the Delivery

document needs to be updated manually with the Pick Quantities as it does not

go through the 3 Way Matching Report

15. As required, complete/review the following fields from the Item Overview tab:

|

Field Name

|

R/O/C

|

Description

|

|

Planned GI

|

R

|

Description of this term

Planned Goods Issue date of the outbound

shipment. Planned Goods Issue date of the outbound

shipment.

Example: 12/13/2005

|

|

Actual GI date

|

O

|

Actual Goods Issue date.

Actual Goods Issue date of the outbound

shipment to the customer, if different from the planned date. Actual Goods Issue date of the outbound

shipment to the customer, if different from the planned date.

Example: 12/12/2005

|

|

Total Weight

|

R

|

The total gross weight

of all articles being ordered

Weight of the shipment. Weight of the shipment.

Example: 40

oz

|

|

Delivery quantity

|

R

|

Quantity of material to

be delivered.

Example: 10

|

16. As required, complete/review the following fields from the Picking tab:

|

Field Name

|

R/O/C

|

Description

|

|

Pick Date/Time

|

R

|

Date/Time the delivery

is planned to be picked for shipment.

|

|

Delivery quantity

|

R

|

Quantity of material to

be delivered.

Example: 10

|

|

Pick quantity

|

R

|

Quantity of an item

which needs to be removed from its current storage location, prepared for

shipping and appears on the printed picking list.

Article quantity that was picked for

shipment Article quantity that was picked for

shipment

|

|

Batch

|

O

|

Number that uniquely

assigns a material manufactured in a lot. The batch material is managed separately

from other sets of the same material. Also, used to describe the running of

multiple non-manual transactions in SAP.

Individual

product number for batch-managed product, if applicable Individual

product number for batch-managed product, if applicable

|

If Pick quantity

is less than Delivery quantity in Delivery

Document, the Delivery quantity field may

be adjusted to match Pick quantity so that

the Post Goods Issue can be executed.

If Pick quantity

is less than Delivery quantity in Delivery

Document, the Delivery quantity field may

be adjusted to match Pick quantity so that

the Post Goods Issue can be executed.

Any variations in quantities that

can be shipped from quantities ordered (listed on the Sales Order), would

require the Sales Order document to be changed to reflect the actual shipped

quantities, prior to updating the Delivery Document with the actual quantity

shipped.

If there is a mismatch in the

carton count from the 3 Way

Matching Report between the Factory, Forwarder/Consolidator and CFS EDI feeds,

manual intervention and investigation is needed. The relevant corrected ASN's

need to be sent again so that there is a 3 way match, which will facilitate the

update of the Delivery Doc and the PGI.

For gift card orders in personal care, the Serial Nos , Special

Processing and UPS/Fedex number

fields will need to be entered in the Delivery Document. This data will need to

be manually entered by the sales associate based on information received from

the DC or vendor.

For gift card orders in personal care, the Serial Nos , Special

Processing and UPS/Fedex number

fields will need to be entered in the Delivery Document. This data will need to

be manually entered by the sales associate based on information received from

the DC or vendor.

17. Perform one of the following:

|

If

|

Then

|

Go To

|

|

Picking gift card articles for GL2 Corporate Sales, if

applicable

|

Gift card Serial Numbers (beginning number and ending

number range) must be entered in the Delivery document.

|

Step 18

|

|

Picking manually

|

|

Step 22

|

18. Click  (the field left of Item in the All

Items area) to select the desired Delivery Item.

(the field left of Item in the All

Items area) to select the desired Delivery Item.

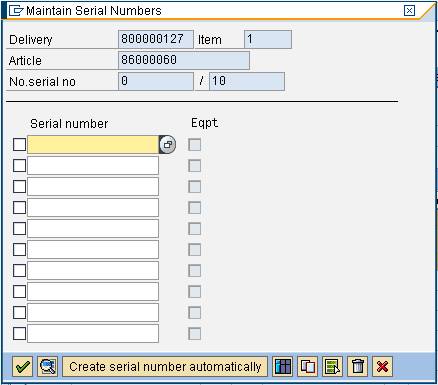

19. From the Menu bar, click Extras to display the Maintain Serial Numbers window.

Maintain

Serial Numbers

20. As required, complete/review the following fields:

|

Field Name

|

R/O/C

|

Description

|

|

Serial number

|

R

|

Number that combined

with a material number uniquely identifies a specific instance of the

material for tracking purposes.

Enter the range of gift card serial

numbers picked for the Delivery. Enter the beginning serial number in the

first Serial number field and the ending

serial number in the next Serial number

field. Enter the range of gift card serial

numbers picked for the Delivery. Enter the beginning serial number in the

first Serial number field and the ending

serial number in the next Serial number

field.

Example: 6000600060006000999

|

21. Click  to accept entry and

continue.

to accept entry and

continue.

Repeat steps

18 - 21 for each Delivery

Item containing a gift card Article.

Repeat steps

18 - 21 for each Delivery

Item containing a gift card Article.

22. As required, complete/review the following fields from the Loading tab:

|

Field Name

|

R/O/C

|

Description

|

|

Loading Date

|

O

|

Date on which an order

was loaded onto the transportation carrier.

Date and time Delivery was loaded into

transportation vehicle for shipment. Date and time Delivery was loaded into

transportation vehicle for shipment.

|

|

Gross weight

|

O

|

Weight of the material,

including packaging.

Gross weight of article that was loaded

for shipment. Gross weight of article that was loaded

for shipment.

|

|

WUn

|

O

|

Weight unit of measure.

Unit of measure for gross weight. Unit of measure for gross weight.

Example: LB

|

23. As required, complete/review the following fields from the Transport tab:

|

Field Name

|

R/O/C

|

Description

|

|

TransptnPlanng

|

O

|

The date by which you

must arrange transportation so that the delivery can reach the customer on

time.

Date and time Delivery needs to be

shipped to reach customer by requested date. Date and time Delivery needs to be

shipped to reach customer by requested date.

|

|

Gross weight

|

O

|

Weight of the material,

including packaging.

Gross weight of article that was loaded

for shipment Gross weight of article that was loaded

for shipment

|

|

WUn

|

O

|

Weight unit of measure.

Unit of measure for gross weight. Unit of measure for gross weight.

Example: LB

|

24. Click  to go to the Delivery XXXX Change Header Details screen.

to go to the Delivery XXXX Change Header Details screen.

Delivery

XXXX Change: Header Details

25. Click  tab to go to the Delivery XXXX Change: Header Details (Texts)

screen.

tab to go to the Delivery XXXX Change: Header Details (Texts)

screen.

Delivery

XXXX Change: Header Details (Texts)

The Texts

tab may be used to enter any pertinent text comment regarding the Delivery

Document.

The Texts

tab may be used to enter any pertinent text comment regarding the Delivery

Document.

Example: Special case packing will be used

26. Select text type (Txt Ty) from those listed.

Txt Ty

of "External/Billing comments" and "Delivery Information" will be displayed in

the Delivery Document and printed on the Shipment Confirmation sent to the

customer, if applicable. Txt Ty of

"Internal comments" will only be displayed in the Delivery Document, not

printed on any output documents.

Txt Ty

of "External/Billing comments" and "Delivery Information" will be displayed in

the Delivery Document and printed on the Shipment Confirmation sent to the

customer, if applicable. Txt Ty of

"Internal comments" will only be displayed in the Delivery Document, not

printed on any output documents.

27. Click  to display any existing

comments for the text type selected.

to display any existing

comments for the text type selected.

28. Click in the large, white text box and type the comment to add to the Delivery

Document.

29. Click  to go to the Delivery XXXX Change: Overview screen.

to go to the Delivery XXXX Change: Overview screen.

Delivery

Retail XXXX Change: Overview

30. Click  to save the changes.

to save the changes.

The system displays the message,

"Delivery XXXX has been saved".

The system displays the message,

"Delivery XXXX has been saved".

31. Click  to exit the transaction.

to exit the transaction.

32. Return to step 3 to select another Delivery

transaction or to exit the procedure.

33. The Change Outbound Delivery activity is complete.

34. Use transaction code VL03N to Display Outbound Delivery

Display

Outbound Delivery

The Delivery document can also be accessed

from the document flow function in the Sales Order.

The Delivery document can also be accessed

from the document flow function in the Sales Order.

35. As required, complete the following field:

|

Field Name

|

R/O/C

|

Description

|

|

Outbound Delivery

|

R

|

Document generated in

SAP that triggers pick, pack and ship activities.

Outbound Delivery Document number. Outbound Delivery Document number.

Example: 80000311

|

36. Click  to go to the Delivery XXXX Display: Overview screen.

to go to the Delivery XXXX Display: Overview screen.

Delivery

XXXX Display: Overview

It

is important to verify that the information displayed in the Ship-to party, Planned

GI, Actual GI date, Total Weight, Article,

Delivery quantity, SU, Description,

Site fields are accurate.

It

is important to verify that the information displayed in the Ship-to party, Planned

GI, Actual GI date, Total Weight, Article,

Delivery quantity, SU, Description,

Site fields are accurate.

Additional

information may be viewed by clicking on the Picking,

Loading, Transport,

Status Overview and Goods Movement Data tabs available from the Delivery XXXX Display: Overview screen.

37. To view additional detail for the Delivery Document, perform one of the

following:

|

If

|

Then

|

|

Requesting display of Picking information

|

Click the Picking tab

|

|

Requesting display of Loading information

|

Click the Loading tab

|

|

Requesting display of Shipping information

|

Click the Transport

tab

|

|

Requesting display of Delivery status information

|

Click the Status Overview

tab

|

|

Requesting display of Goods Movement information

|

Click the Goods Movement

Data tab

|

|

Requesting display of Delivery header data

|

Click

Multiple tabbed areas are available for

display. Multiple tabbed areas are available for

display.

Click  to

return to the Delivery XXXX Display: Overview

screen to

return to the Delivery XXXX Display: Overview

screen

|

|

Requesting display of Delivery comment text

|

Click  to

go to the Delivery XXXX Change: Header Details

screen to

go to the Delivery XXXX Change: Header Details

screen

Click the Texts tab

Click  to

return to the Delivery XXXX Display: Overview

screen to

return to the Delivery XXXX Display: Overview

screen

|

38. Click  to exit the transaction.

to exit the transaction.

39. Return to step 3 to select another Delivery

transaction or to exit the procedure.

40. The Display Outbound Delivery is complete.

41. Use transaction code VL06G to execute the Outbound Deliveries for Goods Issue

Outbound

Deliveries for Goods Issue

42. As required, complete/review the following fields:

|

Field Name

|

R/O/C

|

Description

|

|

Shipping Point/Receiving Pt

|

R

|

Physical location from

which an item is shipped/received.

LBI site from which goods are shipped. A

range of shipping/receiving point values may be entered. The beginning value

is entered in the Shipping Point/Receiving Pt

field and the ending value is entered in the to

field. LBI site from which goods are shipped. A

range of shipping/receiving point values may be entered. The beginning value

is entered in the Shipping Point/Receiving Pt

field and the ending value is entered in the to

field.

Example: Z015

|

|

Pland gds mvmnt date

|

O

|

Date on which the goods

are planned to be moved in the system

This field may be used to indicate a date

or date range as selection criteria for selecting outbound Delivery

Documents. If a date range is entered, the beginning value is entered in the

Pland gds mvmnt date field and the

ending value is entered in the to field. This field may be used to indicate a date

or date range as selection criteria for selecting outbound Delivery

Documents. If a date range is entered, the beginning value is entered in the

Pland gds mvmnt date field and the

ending value is entered in the to field.

|

43. Click  to go to the Goods Issue for Outbound Deliveries to be Posted

screen.

to go to the Goods Issue for Outbound Deliveries to be Posted

screen.

A list of Outbound Delivery Documents

requiring Goods Issue Posting is displayed.

A list of Outbound Delivery Documents

requiring Goods Issue Posting is displayed.

Goods

Issue for Outbound Deliveries to be Posted

44. Click  (to the left of the

Delivery document number) to select the appropriate Delivery Document.

(to the left of the

Delivery document number) to select the appropriate Delivery Document.

45. Click  to update the Delivery

Document with the actual shipping date (the date that the goods left the

shipping point).

to update the Delivery

Document with the actual shipping date (the date that the goods left the

shipping point).

Specify Actual

Goods Issue Date

46. As required, complete/review the following field:

|

Field Name

|

R/O/C

|

Description

|

|

Act. gds mvmnt date

|

R

|

Actual goods movement

date.

Actual date the goods were shipped if

different from the planned ship date. Actual date the goods were shipped if

different from the planned ship date.

Example: 12/12/2005

|

47. Click  to validate the goods

movement date entered.

to validate the goods

movement date entered.

Goods

Issue for Outbound Deliveries to be Posted

The system confirms the goods movements,

indicating transaction success and/or any problems. The message "X successful

and X incorrect goods movement" is displayed.

The system confirms the goods movements,

indicating transaction success and/or any problems. The message "X successful

and X incorrect goods movement" is displayed.

For GL3, The Goods

Issue serves to transfer the ownership of goods between Mast entities and

between Mast and the customer.

For GL3, The Goods

Issue serves to transfer the ownership of goods between Mast entities and

between Mast and the customer.

48. Click  to exit this

transaction.

to exit this

transaction.

49. Go to step 3 to select another Delivery

transaction or to exit this procedure.

50. The Post Goods Issue activity is complete.

51. In order to print or send, use transaction code VL03N to Display Outbound

Delivery

Display

Outbound Delivery

52. As required, complete/review the following field:

|

Field Name

|

R/O/C

|

Description

|

|

Outbound Delivery

|

R

|

Document generated in

SAP that triggers pick, pack and ship activities.

Outbound Delivery Document number. Outbound Delivery Document number.

Example: 80000311

|

Display

Outbound Delivery

53. Select to e-mail and/or

print, if needed

Output

output

There are two types of Delivery Document

output for Personal Care: Delivery Note

and Shipment Confirmation. The Delivery Note is typically sent to the

fulfillment vendor and the Shipment Confirmation

is typically sent to the customer. Delivery output may be printed as hardcopy

or transmitted electronically via e-mail.

There are two types of Delivery Document

output for Personal Care: Delivery Note

and Shipment Confirmation. The Delivery Note is typically sent to the

fulfillment vendor and the Shipment Confirmation

is typically sent to the customer. Delivery output may be printed as hardcopy

or transmitted electronically via e-mail.

54. Click  (field left of Message type in each row of the Output section)

to select the appropriate Delivery Document.

(field left of Message type in each row of the Output section)

to select the appropriate Delivery Document.

Output

output

55. Click  to select the printer,

recipient and other output options.

to select the printer,

recipient and other output options.

Issue

Output

56. As required, complete/review the following fields:

|

Field Name

|

R/O/C

|

Description

|

|

Logical destination

|

R

|

Description of this term

This field specifies the name of the

printer or the e-mail address to direct the Delivery Document output to. If

needed, select "LOCL" in order to print to the default printer of a user This field specifies the name of the

printer or the e-mail address to direct the Delivery Document output to. If

needed, select "LOCL" in order to print to the default printer of a user

Example: Insightprt8

|

|

Recipient

|

R

|

Person who is to receive

the material or service.

The recipient of the printed output will

be included in this field. The recipient of the printed output will

be included in this field.

|

|

Department

|

O

|

Organizational

department to which the cost center created will be assigned. Also, a group

of machines or production lines that do similar manufacturing operations.

|

|

Cover Page Text

|

O

|

Text that is to be

included on the cover page of the Delivery Document output.

|

|

Print Immediately

|

O

|

Indicator used to

specify that the Delivery Document output is to be printed immediately after

completing the transaction.

This option is typically used most often. This option is typically used most often.

|

|

Release after output

|

O

|

Indicator that is used

to release the Delivery after the output print request is processed.

When checked, this option will release

the Delivery after the print request is processed. When checked, this option will release

the Delivery after the print request is processed.

|

57. Click  to establish the

settings.

to establish the

settings.

Output

output

58. Click  to preview a copy of the

Delivery Document output (either Delivery Document or Shipment Confirmation).

to preview a copy of the

Delivery Document output (either Delivery Document or Shipment Confirmation).

A screen shot of each is displayed as an

example.

A screen shot of each is displayed as an

example.

Print

Preview XXXX (Delivery Document)

Print

Preview of XXXX (Shipment confirmation)

59. Click  to go back to the Output output screen (Delivery Document output

selection).

to go back to the Output output screen (Delivery Document output

selection).

60. Click  to print and/or e-mail

output to the vendor as needed.

to print and/or e-mail

output to the vendor as needed.

The system confirms that the e-mail and/or

printed output was successfully generated.

The system confirms that the e-mail and/or

printed output was successfully generated.

For Sell from Stock, if a vendor is

shipping directly to a customer, a fax of the Delivery Document will need to be

manually sent to this vendor if they cannot access this Delivery Document via

the CHub access system.

For Sell from Stock, if a vendor is

shipping directly to a customer, a fax of the Delivery Document will need to be

manually sent to this vendor if they cannot access this Delivery Document via

the CHub access system.

The type of output that will be generated

for the customer (e-mail or printed) is defined in the Customer Master data

record.

The type of output that will be generated

for the customer (e-mail or printed) is defined in the Customer Master data

record.

61. Click  to exit the transaction.

to exit the transaction.

62. Return to step 3 to select another Delivery activity

or to exit the procedure.

63. The printing/emailing Delivery Document activity is complete.

64. Use transaction code VL09 to Reverse Goods Movement

Reverse

goods movement

The Reverse Post Goods Issue is used to

cancel or correct errors in the original Post Goods Issue. After a reversal, a

corrected Post Goods Issue (PGI) for the Delivery may again be executed.

The Reverse Post Goods Issue is used to

cancel or correct errors in the original Post Goods Issue. After a reversal, a

corrected Post Goods Issue (PGI) for the Delivery may again be executed.

65. As required, complete/review the following fields:

|

Field Name

|

R/O/C

|

Description

|

|

Shipping point

|

O

|

Physical location from

which an item is shipped.

LBI site from which goods are shipped. A

range of shipping point values may be entered. The beginning value is entered

in the Shipping Point field and the

ending value is entered in the to field.

This may comprise of a vendor site or warehouse for personal care and

production office or warehouse for apparel LBI site from which goods are shipped. A

range of shipping point values may be entered. The beginning value is entered

in the Shipping Point field and the

ending value is entered in the to field.

This may comprise of a vendor site or warehouse for personal care and

production office or warehouse for apparel

Example: Z015

|

|

Goods movement date

|

O

|

The date the Post Goods

Issue was completed.

A range of dates may be entered. The

beginning date is entered in the Goods movement

date field and the ending date is entered in the to field. A range of dates may be entered. The

beginning date is entered in the Goods movement

date field and the ending date is entered in the to field.

|

|

Inbound / outbound delivery

|

O

|

Description of this term

Outbound Delivery Document number. A

range of Delivery Document values may be entered. The beginning value is

entered in the Inbound/outbound delivery

field and the ending value is entered in the to

field. Outbound Delivery Document number. A

range of Delivery Document values may be entered. The beginning value is

entered in the Inbound/outbound delivery

field and the ending value is entered in the to

field.

Example: 80000311

|

66. Perform one of the following:

|

If

|

Then

|

|

Selecting from both Inbound and Outbound Delivery

Documents

|

Click  Inbound Delivs & Outbound Delivs Inbound Delivs & Outbound Delivs

|

|

Selecting from Outbound Delivery Documents only

|

Click  Outbound del. Outbound del.

Use this option for Sales Order shipments

to customers. Use this option for Sales Order shipments

to customers.

|

|

Selecting from Inbound Delivery Documents only

|

Click  Inbound dlvs Inbound dlvs

Use this option for Inbound Deliveries

from vendors. Use this option for Inbound Deliveries

from vendors.

|

These fields are used as selection criteria

to return a list of Delivery Documents matching the criteria entered.

These fields are used as selection criteria

to return a list of Delivery Documents matching the criteria entered.

67. Click  to display the list of

Delivery Documents matching selection criteria supplied.

to display the list of

Delivery Documents matching selection criteria supplied.

Reverse

goods movement

68. Click  (field left of Delivery in each row) to select the appropriate

Delivery Document.

(field left of Delivery in each row) to select the appropriate

Delivery Document.

69. Click  to reverse the Post

Goods Issue of the selected Delivery Document.

to reverse the Post

Goods Issue of the selected Delivery Document.

A confirmation message box will be

displayed.

A confirmation message box will be

displayed.

Confirm.

Prompt

70. Click  to confirm the reversal

of the previous Post Goods Issue.

to confirm the reversal

of the previous Post Goods Issue.

The Error

log for reversal: Display messages window will be displayed. This

window lists the system messages that indicate the success of the transaction

or any errors that may have occurred. The colored boxes in the Typ column indicate success (green), warning

(yellow) and error (red).

The Error

log for reversal: Display messages window will be displayed. This

window lists the system messages that indicate the success of the transaction

or any errors that may have occurred. The colored boxes in the Typ column indicate success (green), warning

(yellow) and error (red).

Error log

for reversal: Display messages

The Reverse Post Goods Issue will have

implications on inventory movement and accounting journal entries.

The Reverse Post Goods Issue will have

implications on inventory movement and accounting journal entries.

It is not advisable to

Reverse Post Goods Issue if the Billing document output has been generated

already. If only the Billing doc has been created in SAP but not sent to the

customer, then cancel the Billing doc followed by the reversal of the Post

Goods Issue

It is not advisable to

Reverse Post Goods Issue if the Billing document output has been generated

already. If only the Billing doc has been created in SAP but not sent to the

customer, then cancel the Billing doc followed by the reversal of the Post

Goods Issue

71. Click  to acknowledge the Display messages and complete the transaction.

to acknowledge the Display messages and complete the transaction.

Reverse

goods movement

72. Click  to exit the transaction.

to exit the transaction.

73. Go to step 3 to select another Delivery

transaction or to exit this procedure.

74. The Post Goods Issue Reversal activity is complete.

75. This

procedure is now complete.

Result

Depending upon the transaction used, one of the following

will result:

1) A

Sales Order Delivery Document was created, changed or displayed

2) A

Post Goods Issue was completed for the Delivery

3) The

Delivery Document output was sent to the fulfillment vendor and the Shipment

Confirmation output was sent to the customer (for personal care)

4) The

Post Goods Issue for the Delivery is reversed. Inventory quantities are

reinstated

Comments

The creation of the Delivery Document and Post Goods Issue

execution is followed by the Proof of Delivery (if needed) and the creation of

the Billing Document.

![]() Retailing

Retailing

![]() Purchasing

Purchasing ![]() Requirements planning

Requirements planning ![]() Environment

Environment ![]() Allocation

Allocation ![]() Environment

Environment ![]() Shipping

Shipping ![]() Delivery

Delivery

![]() VL01N to go to the Create

Outbound Delivery with Order Reference screen.

VL01N to go to the Create

Outbound Delivery with Order Reference screen.![]() Retailing

Retailing

![]() Purchasing

Purchasing ![]() Requirements planning

Requirements planning ![]() Environment

Environment ![]() Allocation

Allocation ![]() Environment

Environment ![]() Shipping

Shipping ![]() Delivery

Delivery

![]() VL02N to go to the Change

Outbound Delivery screen

VL02N to go to the Change

Outbound Delivery screen![]() Retailing

Retailing

![]() Purchasing

Purchasing ![]() Requirements planning

Requirements planning ![]() Environment

Environment ![]() Allocation

Allocation ![]() Environment

Environment ![]() Shipping

Shipping ![]() Delivery

Delivery

![]() VL03N to go to the Display

Outbound Delivery screen

VL03N to go to the Display

Outbound Delivery screen![]() Retailing

Retailing

![]() Purchasing

Purchasing ![]() Requirements planning

Requirements planning ![]() Environment

Environment ![]() Allocation

Allocation ![]() Environment

Environment ![]() Shipping

Shipping ![]() Delivery

Delivery

![]() Picking

Picking ![]() Warehouse management

Warehouse management ![]() Subsequent Functions

Subsequent Functions ![]() Goods Issue

Goods Issue ![]() VL06G to go to the Outbound Deliveries

for Goods Issue screen

VL06G to go to the Outbound Deliveries

for Goods Issue screen![]() Retailing

Retailing

![]() Purchasing

Purchasing ![]() Requirements planning

Requirements planning ![]() Environment

Environment ![]() Allocation

Allocation ![]() Environment

Environment ![]() Shipping

Shipping ![]() Delivery

Delivery

![]() Picking

Picking ![]() Warehouse management

Warehouse management ![]() Subsequent Functions

Subsequent Functions ![]() Goods Issue

Goods Issue ![]() VL09 to go to the Reverse Goods

Movement screen

VL09 to go to the Reverse Goods

Movement screen